Why Geothermal Ground Loop Sizing Matters for Your Texas Home

Geothermal ground loop sizing determines how much underground piping your system needs to heat and cool your home efficiently. If you’re considering a geothermal heat pump in Granbury, TX, getting the loop size right is critical. An undersized loop forces your system to work harder, driving up electricity bills and reducing comfort. An oversized loop wastes money on unnecessary installation costs and can cause short-cycling, which reduces efficiency and humidity control. The right size depends on your home’s heating and cooling load, soil conditions, available land, and the heat pump’s capacity.

If you’re exploring geothermal heating and cooling benefits for your home, or ready to schedule a geothermal system consultation, understanding loop sizing helps you make informed decisions.

Quick Reference: Key Factors in Geothermal Ground Loop Sizing

- Building Load: Your home’s heating and cooling demand (measured in tons)

- Soil Type: Rock and clay transfer heat better than sand

- Climate: Texas heating vs. cooling needs affect loop length

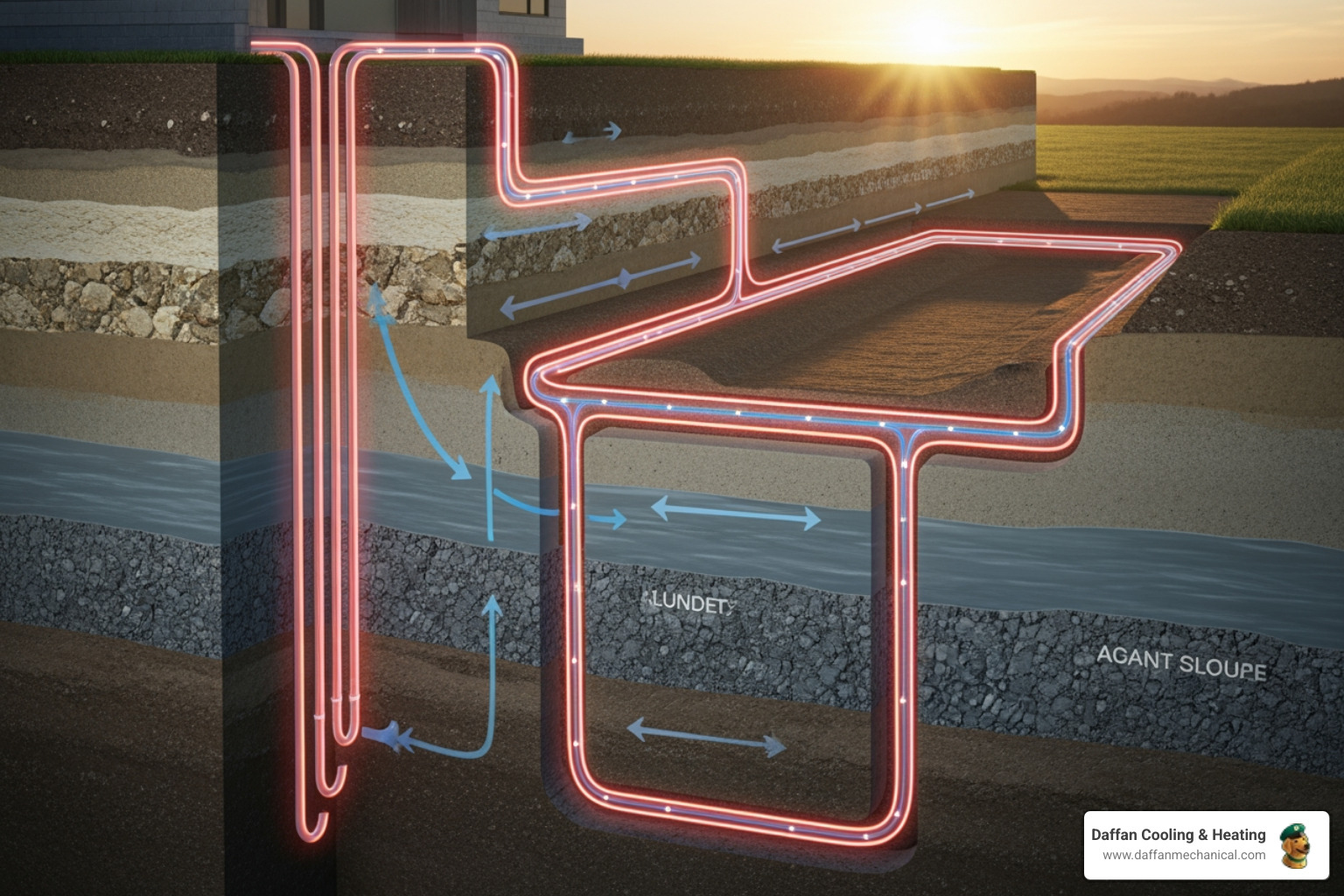

- Loop Configuration: Vertical (100-500 ft deep), horizontal (6-10 ft deep), or pond/lake

- Rule of Thumb: 150-200 feet of vertical bore per ton in heating climates; 2,500 ft² per ton for horizontal loops

- Flow Rate: 3 gallons per minute (GPM) per ton of capacity

- Professional Analysis: ACCA Manual J heat loss/gain calculation is essential

Most homeowners in Hood County need a 3- to 5-ton system. A typical 3-ton vertical system requires about 600 feet of bore (two 300-foot boreholes). A horizontal system for the same home needs two 300-foot trenches with multiple pipe loops, totaling 3,600 linear feet of piping underground.

What is a Geothermal Ground Loop?

At Daffan Cooling & Heating, we’re passionate about bringing efficient, sustainable comfort to our Granbury, TX, neighbors. A geothermal ground loop is the hidden hero of a geothermal heating and cooling system. It’s essentially a series of durable, U-shaped plastic pipes buried in the ground, deep enough to reach the earth’s consistent, year-round temperatures.

How does it work its magic? An electric pump circulates a heat transfer fluid (usually water mixed with an environmentally friendly antifreeze) through these underground pipes. In the cooler months, as the fluid travels through the loop, it absorbs heat from the earth, which maintains a stable temperature of approximately 50-60°F just a few feet below the surface, even when it’s chilly outside. This warmed fluid then returns to your home, where the geothermal heat pump extracts the heat and distributes it indoors through your ductwork. When the Texas summer heat arrives, the process reverses: the system removes heat from your home and transfers it into the cooler earth through the same ground loop.

This constant temperature exchange makes geothermal systems incredibly efficient. Instead of burning fossil fuels to create heat, or expending vast amounts of energy to cool air, we’re simply moving existing heat to where it’s needed. This translates to significant energy savings, with ground source heat pumps reducing heating costs by up to 60% compared to an electric furnace. For homeowners in Granbury and throughout Hood County, this efficiency means a more comfortable home and a lighter impact on your wallet and the environment. Geothermal systems are truly a renewable energy source, using the earth’s stored solar energy for year-round comfort.

Ground Loop Configurations: Finding the Right Fit for Your Property

Choosing the right ground loop configuration is a pivotal step in designing your geothermal system. It depends heavily on your property’s size, soil conditions, and specific needs. We’ll help you steer the options to find the perfect fit for your Granbury, TX, home. The primary types include vertical, horizontal, pond/lake, and open-loop systems, each with unique land area requirements and installation processes. Understanding these differences is key to a successful geothermal installation, especially when considering a switch from geothermal heat pumps vs. traditional systems.

Vertical Ground Loops

Vertical ground loops are ideal for properties with limited land area, making them a popular choice for urban or suburban homes in Hood County where space is at a premium. This configuration involves drilling deep boreholes, typically between 100 to 500 feet deep, into which U-shaped pipes are inserted. These boreholes are usually spaced 10 to 20 feet apart.

The installation process for vertical loops involves specialized drilling equipment. While it’s a more intensive initial step, the surface disruption is minimal once the drilling is complete. The boreholes are then filled with a thermally conductive grout from bottom to top. This grout ensures good thermal contact between the pipes and the surrounding earth, and also seals off aquifers to prevent groundwater contamination. The minimal surface footprint means your landscaping remains largely undisturbed, which is a big plus for many homeowners.

Horizontal Ground Loops

If you have ample land available, horizontal ground loops can be a more cost-effective installation option, as they typically require trenching rather than drilling. These loops are installed in shallow trenches, usually 6 to 10 feet deep, to ensure they are safely below the frost line and reach the earth’s stable temperature zone. While 6 feet is the minimum, 8 feet is often more ideal to avoid any surface interference.

The installation involves digging trenches hundreds of feet long. For example, a horizontal loop for a mid-sized home might require two 300-foot trenches, 8 feet deep and 3.5 feet wide, each containing three loops, for a total of 3,600 linear feet of piping. These loops can be laid out in straight parallel lines or coiled into a “slinky” shape to fit more piping into a smaller trench area, though this requires more pipe. The primary disruption with horizontal loops is the significant trenching involved, which can temporarily affect a large portion of your yard. We typically recommend allowing the ground to settle for about a year before undertaking extensive landscaping.

Pond, Lake, and Open-Loop Systems

For properties near a suitable body of water, pond or lake loop systems offer another closed-loop option. These involve submerging coils of pipe at least 8 feet deep in a pond or lake. This method can be very efficient as water bodies are excellent at transferring heat. However, it requires careful consideration of water body size, depth, and proper anchoring of the loops. Regulations and permits, such as those that might be required by local water authorities, are crucial for these installations.

Open-loop geothermal systems, sometimes called “pump and dump” systems, use groundwater directly. They extract water from a well, transfer its heat, and then return the water to an aquifer or discharge it to a surface body. While potentially very efficient (the water entering an open loop system is typically approximately 6°C warmer than a closed loop system), open-loop systems require a plentiful and constant groundwater source and extensive water quality testing to ensure compatibility with the system and prevent issues like mineral buildup. Due to the need for water rights licenses and environmental considerations, these systems are less common for residential applications in our service areas of Granbury and Hood County.

The Critical Factors of Geothermal Ground Loop Sizing

Accurately sizing your geothermal ground loop is not just about digging some trenches or drilling some holes; it’s a precise science that ensures your system delivers optimal comfort and efficiency for decades. At Daffan Cooling & Heating, we rely on expert analysis to design a system perfectly custom to your Granbury home. This process considers several critical factors, from your home’s unique characteristics to the local geology and climate of Hood County. The goal is to match the ground loop to the heat pump’s capacity and your home’s specific heating and cooling needs, ensuring the long-term success of your geothermal heating and cooling system.

The Role of a Heat Loss/Gain Analysis

The absolute first step in any accurate geothermal design is a thorough heat loss/gain analysis. This isn’t just a guess; it’s a detailed calculation of how much heating your home needs on the coldest winter day and how much cooling it needs on the hottest summer day. We use industry-standard methodologies, such as the ACCA Manual J, to perform these calculations. This analysis considers numerous factors:

- Home Size and Layout: Square footage, number of rooms, and ceiling heights.

- Insulation Levels: Walls, attic, and floor insulation.

- Window and Door Quality: Energy efficiency ratings, number, and orientation.

- Air Tightness: How well your home prevents drafts and air infiltration.

- Occupancy: The number of people living in the home.

- Internal Heat Gains: From appliances, lighting, and electronics.

The heat loss/gain calculation provides us with your home’s peak heating and cooling load, usually expressed in BTUs per hour. For example, a 1,900 sq ft building might have a peak heat loss of 38,000 BTUs per hour. This precise number is then used to select the appropriately sized heat pump, as 12,000 BTUs per hour equals one ton of capacity. Not spending enough time on this crucial calculation is one of the top mistakes geothermal designers can make, as it directly impacts system sizing and efficiency. You can learn more about this critical step on our system sizing page.

Soil Conditions and Climate

The ground itself is a key player in your geothermal system, and its characteristics directly influence geothermal ground loop sizing.

- Soil Type Impact: Different soil types have varying thermal conductivities. Dense soils like rock and clay are excellent at transferring heat, meaning a smaller loop field might be sufficient. Sandy soils, which retain less water, are less efficient and would require a larger loop field to achieve the same heat transfer.

- Ground Moisture Levels: Water content in the soil significantly improves its thermal mass and conductivity. “Swampy” areas, for instance, are actually ideal for geothermal loops because the water helps retain and transfer heat more effectively. Drier ground generally requires a larger loop field.

- Deep Earth Temperature in Texas: While surface temperatures in Granbury, TX, fluctuate wildly, the earth’s temperature remains remarkably stable just a few feet below the surface. In our region, this consistent temperature is typically around 50-60°F at about 10 feet deep. This stable temperature is what makes geothermal viable in both our hot summers and cooler winters.

- Sizing for Heating vs. Cooling Needs: For most homes in our Hood County service area, cooling loads often dominate due to our long, hot summers. This means the ground loop must be sized effectively to dissipate heat into the earth during cooling cycles, preventing the ground from becoming oversaturated with heat over time. In heating-dominated climates, the primary concern would be extracting enough heat from the ground. Our local climate dictates a balanced approach to geothermal ground loop sizing to ensure year-round comfort. Our partners at Geothermal HVAC Systems Service Resources provide more insights into these considerations.

Heat Pump Tonnage and Flow Rate

Once the heat loss/gain analysis is complete, we determine the appropriate heat pump size, measured in “tons” (1 ton = 12,000 BTUs per hour). This heat pump tonnage directly dictates the required length of your ground loop. A larger heating and cooling load requires a larger heat pump, and consequently, a larger ground loop.

- Matching Loop to Heat Pump Capacity: For a 3-ton unit, for example, we’ll need approximately 600 feet of vertical bore (based on a rule of thumb of 200 feet per ton in heating-dominated climates, adjusted for our local conditions). For horizontal loops, it’s about 2,500 square feet of land area per ton.

- Required Fluid Flow Rate (GPM): For efficient operation, the fluid circulating through the ground loop needs to move at a specific rate. The industry standard is 3 gallons per minute (GPM) of flow per ton of heating capacity. So, a 3-ton system would require a flow rate of 9 GPM. This ensures adequate heat exchange between the fluid and the earth.

- Performance Metrics (COP and EER): The efficiency of your geothermal system is measured by its Coefficient of Performance (COP) for heating and Energy Efficiency Ratio (EER) for cooling. Geothermal systems deliver 3-5 units of energy for every unit of electricity consumed, achieving COPs between 3.0 and 5.0. Proper geothermal ground loop sizing directly impacts these metrics; an undersized loop will force the system to work harder, reducing its COP and EER, and ultimately increasing your operating costs. This is why choosing a geothermal heat pump is such a smart choice for long-term savings.

How Sizing and Design Impact Performance

The meticulous process of geothermal ground loop sizing and design is paramount to the overall efficiency, longevity, and performance of your entire geothermal system. It’s not just about installing pipes; it’s about creating a perfectly balanced exchange system with the earth. At Daffan Cooling & Heating, we ensure every detail is considered to maximize your comfort and savings. This careful planning ensures that your geothermal heat pumps for home heating operate at their peak.

The Consequences of Improper Geothermal Ground Loop Sizing

Getting the geothermal ground loop sizing wrong can lead to a host of problems that undermine the benefits of geothermal technology:

-

Undersized Loops: If the loop is too short, it can’t efficiently absorb or dissipate enough heat. This forces your geothermal heat pump to work harder and longer, leading to:

- Overworked System: Increased wear and tear on components, potentially shortening the lifespan of your heat pump (which is typically 20-25 years, compared to 50-100 years for the loops themselves).

- Reduced Efficiency: Lower COP and EER values, meaning your system uses more electricity to deliver the same amount of heating or cooling.

- Higher Utility Bills: The very thing you installed geothermal to reduce!

- Error Warnings: The system might struggle to maintain desired temperatures, triggering performance issues.

-

Oversized Loops: While it might seem like more is better, an oversized loop can also cause issues:

- Wasted Investment: You’re paying for more drilling, digging, and piping than your home actually needs.

- Short-Cycling: The system may satisfy the thermostat call too quickly, leading to frequent on/off cycles. This reduces efficiency, increases wear, and most noticeably, results in poor humidity control during cooling cycles, leaving your home feeling clammy.

The goal is always the “just right” size, ensuring optimal heat transfer without overspending or compromising comfort.

Key Details in Geothermal Ground Loop Sizing and Design

Beyond the overall length, several other design elements are crucial for long-term success:

- Loop Depth and Spacing:

- Depth: For horizontal loops, a minimum of 6 feet, ideally 8-10 feet, ensures consistent temperatures and protection from surface activities. Vertical loops are drilled 100-500 feet deep.

- Spacing: Proper spacing between loop pipes (e.g., 10-20 feet apart for vertical bores) is essential to prevent “thermal interference,” where one pipe’s heat exchange affects another, reducing overall system efficiency.

- Pipe Materials (HDPE): The pipes used for ground loops are typically made from high-density polyethylene (HDPE) or cross-linked polyethylene (PEXa). These materials are incredibly durable, corrosion-resistant, and can even withstand damage from seismic activity, according to the Plastic Pipes Institute. HDPE is a food-grade plastic, often used for milk jugs, highlighting its safety and robustness.

- Expected Lifespan: Geothermal ground loops are built to last! Properly installed, these pipes can last 50+ years, with some sources suggesting up to 100 years. They are truly considered a permanent fixture of your property.

- Circulating Fluid: The fluid circulating through closed-loop systems is typically a mixture of water and a small amount of environmentally friendly, non-toxic antifreeze, such as propylene glycol. This mixture lowers the fluid’s freezing point, ensuring operation even if ground temperatures approach freezing. The specific properties of this fluid (e.g., specific gravity, thermal capacity) are factored into the geothermal ground loop sizing calculations.

Installation and Long-Term Care

The installation process for geothermal loops is a significant undertaking, but with Daffan Cooling & Heating, we prioritize careful planning and execution to minimize disruption and ensure system integrity.

- Potential for Underground Damage: While HDPE ground loops are robust, damage can occur from mechanical injury, such as digging post holes or other significant excavation projects. Leaks can also arise from improper fusion joints during installation. This highlights the importance of choosing experienced, accredited installers who use proper techniques like heat fusion for all pipe connections, avoiding buried mechanical fittings.

- Leak Prevention with Heat Fusion: All piping joints in a geothermal ground loop should be connected using heat fusion, creating a seamless, leak-proof bond stronger than the pipe itself. Before backfilling, we rigorously pressurize and leak-test the entire loop system to ensure its integrity.

- Restrictions on Planting or Building: Once buried, ground loops are safe to drive over. However, we generally recommend against planting trees directly over ground loops. Tree root systems can potentially grow around the pipes, and the soil around the pipes might experience temperature fluctuations that could impact the tree. For other structures, a qualified installer can advise on safe distances.

- Maintenance Requirements: This is one of the best parts about ground loops: they are virtually maintenance-free! Once installed and operating, they do not require cleaning, re-charging, or regular check-ups. The indoor heat pump unit will require standard HVAC maintenance, but the underground component is designed for decades of reliable, hands-off operation. For our customers in Granbury, TX, and surrounding areas like Benbrook, Weatherford, and Stephenville, this means peace of mind. We provide comprehensive services for your HVAC/Granbury, TX/Geothermal Heat Pump system.

Frequently Asked Questions about Ground Loops

We know you have questions about this innovative technology, and we’re here to provide clear, expert answers. Here are some of the most common inquiries we receive regarding geothermal ground loops.

How does the ground loop size affect the system’s efficiency?

The size of your ground loop is directly tied to the efficiency and performance of your entire geothermal system. Correct geothermal ground loop sizing ensures an optimal heat exchange between your home and the earth.

- Undersizing: An undersized loop cannot effectively transfer enough heat, forcing the heat pump to work harder. This leads to higher electricity consumption, reduced Coefficient of Performance (COP) and Energy Efficiency Ratio (EER), and ultimately, higher energy bills. It’s like trying to drink through a tiny straw—your system struggles.

- Oversizing: While not as detrimental as undersizing, an oversized loop represents an unnecessary upfront cost. It can also lead to short-cycling, where the heat pump turns on and off too frequently. This reduces overall efficiency, especially in cooling mode where it can impair humidity removal, making your home feel less comfortable.

A properly sized loop, determined through a meticulous 4-step guide to designing geothermal systems, maximizes the system’s efficiency, longevity, and your comfort.

What maintenance does a geothermal ground loop require?

The good news is, the buried ground loop itself is virtually maintenance-free! Once properly installed and leak-tested, it’s designed to operate without intervention for 50 to 100 years. You won’t need to clean it, recharge it, or perform any regular upkeep on the underground components.

However, the indoor geothermal heat pump unit still requires standard HVAC maintenance, similar to a traditional furnace or air conditioner. This includes routine filter changes, coil cleaning, and periodic checks of refrigerant levels. We offer comprehensive HVAC/Weatherford, TX/Geothermal Heating services to keep your entire system running smoothly and efficiently.

Can radon enter a home through the ground loop installation?

The installation of a geothermal ground loop system, when done by qualified professionals following best practices, does not inherently increase the risk of radon entering your home. Radon is a naturally occurring radioactive gas that can seep into homes through cracks in foundations or other openings in contact with the soil.

During geothermal installation, any penetrations made through the foundation (for the pipes connecting to the indoor unit) are carefully sealed. This sealing process is designed to maintain your home’s thermal envelope and prevent the infiltration of gases like radon. If you have concerns about radon levels in your home, we recommend contacting a radon mitigation professional for testing and advice, independently of your geothermal system.

Ensure Optimal Performance with Professional Geothermal Design

At Daffan Cooling & Heating, we believe in doing things right the first time. When it comes to geothermal ground loop sizing and design, accuracy is everything. This is not a task for guesswork or generic estimates. Our team of experts understands that a properly designed and installed geothermal system is an investment in your home’s comfort, efficiency, and future.

We carefully perform comprehensive heat loss/gain analyses, taking into account every unique aspect of your Granbury, TX, home and the local Hood County geology. We consider soil conditions, climate specifics, and your heat pump’s exact specifications to ensure your ground loop is perfectly sized for optimal performance. Our commitment to excellence means we don’t just install systems; we design solutions that are custom to you.

Trust Daffan Cooling & Heating to provide you with expert geothermal services, ensuring your system delivers maximum savings and comfort for decades to come. Contact us for your geothermal system needs and experience the Daffan difference.